Jablite Claymaster Board

Jablite Claymaster Board - 75mm / 8 is backordered and will ship as soon as it is back in stock.

Couldn't load collection availability

Delivery charges will vary depending on your location.

To find out delivery cost to your postcode, add the products your require to your basket and then review your basket, entering the delivery postcode

We look to dispatch all products same-day where possible, we use a close network of couriers we have worked alongside for a number of years and will share any and all shipping updates with you directly.

When Is Claymaster Required?

When you live in a clay soil area, some unique challenges present themselves during construction projects. In particular, the pressure exerted by concrete on those clay soil can create a process known as clay heave during the life of the building.

The solution is to use a clay heave board and one of the best known is Claymaster. Let’s look at what it is, how it works and how you install the products.

What is Claymaster?

Claymaster is a clay heave protection product that is used to prevent issues with a building’s foundations when they have been built into clay soils, especially those with a high ratio of mineral particles. This movement happens due to the pressure of the concrete and the moisture that is naturally present and can cause real structural problems to the building if left unchecked.

The products tend to be used where there are shrinkable clays. These are soils that have a large proportion of mineral particles but that is also less than 0.002mm in diameter. This soil is very solid when it is wet but the problem comes when it dries out, leaving a crumbly structure that isn’t great for foundations.

The solution is to use a Claymaster product to reduce the pressure from the concrete. 75mm Claymaster Board is the most popular while the 50mm Claymaster and 100mm Claymaster boards can be used in different situations.

Benefits of Claymaster boards

Claymaster boards are a popular way to deal with this problem because they offer a permanent solution to the issue of clay heave. The boards are easy to install and there’s very little compression due to concrete casting.

Furthermore, there’s no specialist equipment or even knowledge needed to install them. The boards are moisture resistant and lightweight as well as being very durable so they make for a cost-effective solution to the issue. They are also A+ rated in the BRE Green Guide to Specification.

How to install Claymaster

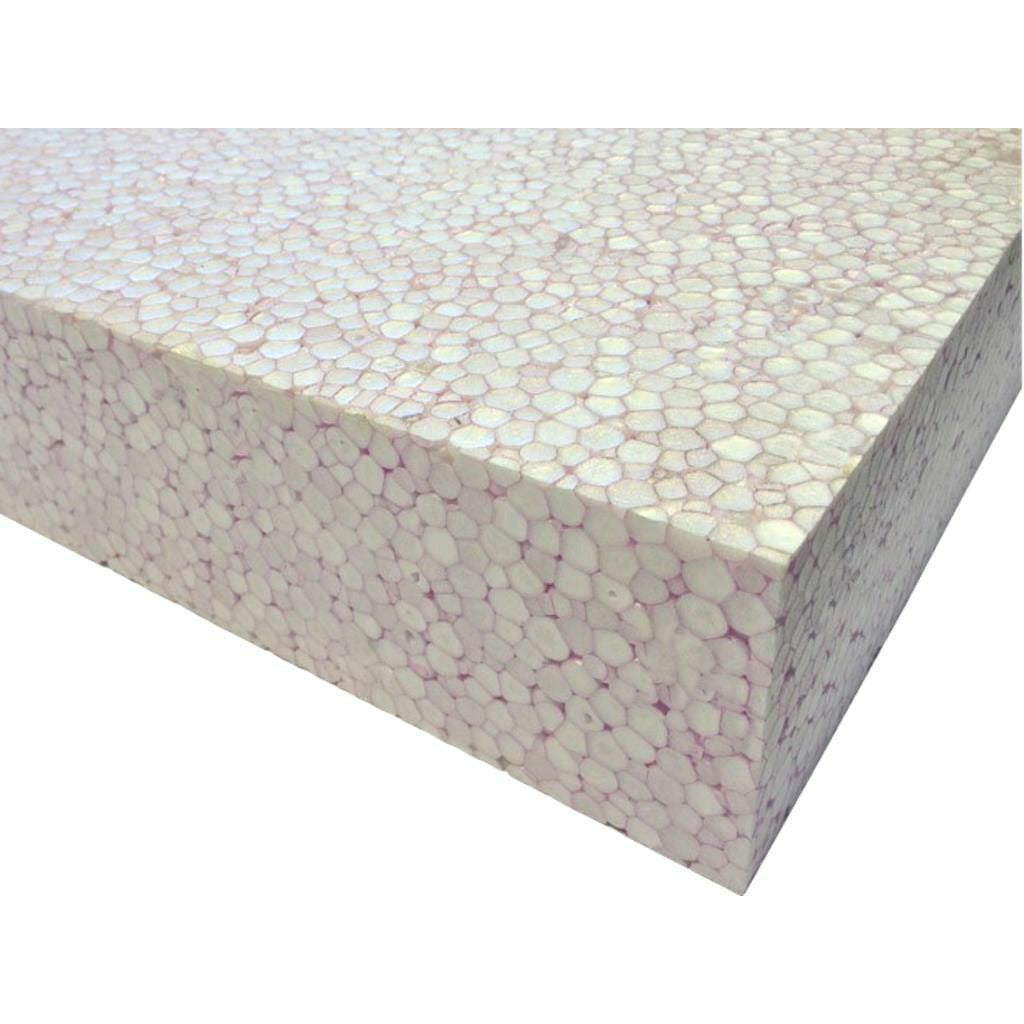

Claymaster boards are a pink colour to make them easy to spot and have enough compressive strength to withstand up to 600mm of wet concrete being placed directly onto them.

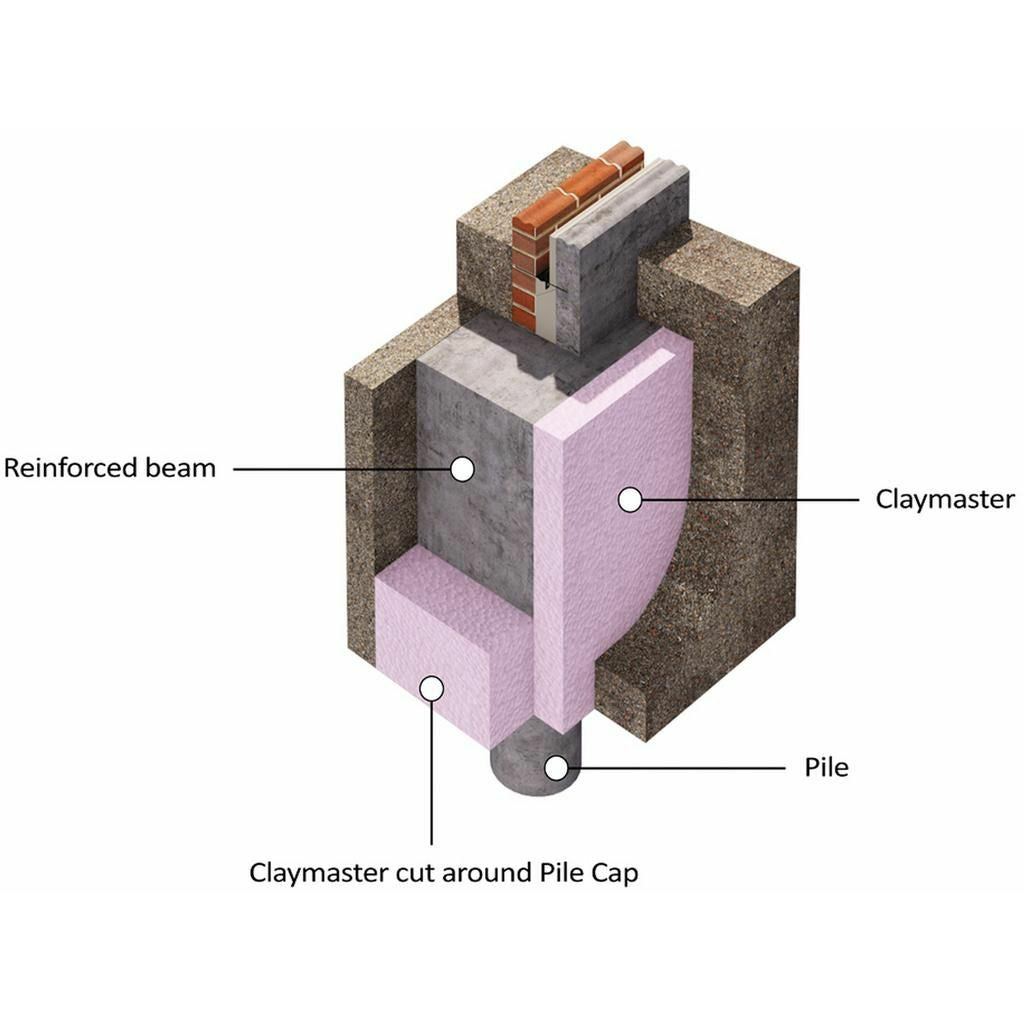

To install them around piled ground beams, trenches should be excavated as normal accommodating the thickness of Claymaster being used. The trench needs to have a flat bottom and granular fill or even concrete added to the bottom to achieve this.

Boards are laid at the bottom of the length, making sure that the full width is lined and the boards butt tightly together. The ground beam should then be placed with the right side, normally an inside face, lined with Claymaster to the required depth.

Supports and restraints are used to then keep everything in position during the placement of the concrete and spacer blocks can be used at the sides or vertical Claymaster boards positioned after the ground beam is cast.

Top quality solutions

Claymaster boards offer a top quality solution to the problem of clay soils and their potential for movement after construction. They are easy to install and require no special equipment so it is easy to bring them into any project where needed.

Description

Description

When Is Claymaster Required?

When you live in a clay soil area, some unique challenges present themselves during construction projects. In particular, the pressure exerted by concrete on those clay soil can create a process known as clay heave during the life of the building.

The solution is to use a clay heave board and one of the best known is Claymaster. Let’s look at what it is, how it works and how you install the products.

What is Claymaster?

Claymaster is a clay heave protection product that is used to prevent issues with a building’s foundations when they have been built into clay soils, especially those with a high ratio of mineral particles. This movement happens due to the pressure of the concrete and the moisture that is naturally present and can cause real structural problems to the building if left unchecked.

The products tend to be used where there are shrinkable clays. These are soils that have a large proportion of mineral particles but that is also less than 0.002mm in diameter. This soil is very solid when it is wet but the problem comes when it dries out, leaving a crumbly structure that isn’t great for foundations.

The solution is to use a Claymaster product to reduce the pressure from the concrete. 75mm Claymaster Board is the most popular while the 50mm Claymaster and 100mm Claymaster boards can be used in different situations.

Benefits of Claymaster boards

Claymaster boards are a popular way to deal with this problem because they offer a permanent solution to the issue of clay heave. The boards are easy to install and there’s very little compression due to concrete casting.

Furthermore, there’s no specialist equipment or even knowledge needed to install them. The boards are moisture resistant and lightweight as well as being very durable so they make for a cost-effective solution to the issue. They are also A+ rated in the BRE Green Guide to Specification.

How to install Claymaster

Claymaster boards are a pink colour to make them easy to spot and have enough compressive strength to withstand up to 600mm of wet concrete being placed directly onto them.

To install them around piled ground beams, trenches should be excavated as normal accommodating the thickness of Claymaster being used. The trench needs to have a flat bottom and granular fill or even concrete added to the bottom to achieve this.

Boards are laid at the bottom of the length, making sure that the full width is lined and the boards butt tightly together. The ground beam should then be placed with the right side, normally an inside face, lined with Claymaster to the required depth.

Supports and restraints are used to then keep everything in position during the placement of the concrete and spacer blocks can be used at the sides or vertical Claymaster boards positioned after the ground beam is cast.

Top quality solutions

Claymaster boards offer a top quality solution to the problem of clay soils and their potential for movement after construction. They are easy to install and require no special equipment so it is easy to bring them into any project where needed.

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Our customers tell it better than we do!

Excellent Delivery Service

Order arrived early in morning, delivery staff were excellent and able to place order as close as possible to where I required it. excellent communication through out delivery and after delivery.

Great Experience

Great experience Really pleased with the way my order was dealt with and delivery arrived as advised.

Good product and service

Good product, reasonable price, great service and good customer follow-up. Would recommend and use again.

Great Company

Great company, great product. Delivery was very speedy and items was delivered professionally by a very helpful driver. Would highly recommend.

Great quality wood and fast delivery

Great quality wood and fast delivery The company reached out to make sure that everything was good and the delivery went fine

Excellent service from a great company

Ordered 2T of midnight blue slate chipping (2 pallets of 50 bags each) Very nice product at a great price. Contacted quickly after order to arrange a suitable delivery date. Delivery was as arranged. Customer service is excellent including follow up call to ensure everything went well. All in all I would highly recommend Armstrong Cheshire.

Great Customer Relations

Due to a mistake in communication ( mostly my mistake) the first delivery of bulk aggregate went to an address I used to live at. After asking to have a replacement delivery to the correct address Armstrong Cheshire re-scheduled the delivery within 3 days and with fantastic customer relations. I cannot recommend this company enough.

Ultra Fast Delivery

Ultra fast delivery, technically superlative company, their products are light years ahead of all others. Unbelievable prices. I have been in construction for nearly 70 years now and am still working every day. This company is why I keep getting up in a morning. Thank you dear sirs/ Madam for making life easier

Steel Lintel

Easy to pick product online, said 10 days delivery but got the product in 4 days, excellent service and prices